Fill all information details to consult with us to get services from us

Population growth and rising individual electricity use are driving soaring growth in the electricity market. Power that can be counted on 24/7 is essential to every nation's progress. Electricity is transmitted and distributed in a wide range of settings, from power plants to industrial complexes. Insulators are required for all electrical wiring. Insulators for electrical currents are essential for protecting both humans and electronics.

Insulators prevent electricity from flowing through them. Insulators are very poor conductors of electricity and have a very high resistance. In every single electrical circuit, insulators play a crucial role. Insulators prevent electricity from leaking out of a circuit, protecting people and allowing the circuit to function reliably. Electrical circuits as well as equipment benefit from insulators because they keep them safe from outside interference. Power transmission lines rely on electrical insulators for structural support. As they are installed in power transmission lines, electrical insulators must be robust enough to bear pressures.

In an electrical system, an insulator manufactured by Radiant Enterprises, one of the most trusted and noteworthy electrical insulation manufacturers in India, is utilised whenever there is a need to stop the unintended flow of electricity from an energised conductor or other conducting components. As a result of the extremely high resistance it offers, virtually no current can move through it. Insulators, in general, contain only the traceable amount of electrons that are free, which means that they nearly never allow electrical current to pass through them. Insulators undergo a process known as "insulation breakdown" when they are subjected to a voltage that is sufficiently high (referred to as the "breakdown voltage"). This causes the insulators to turn into conductors.

To do their jobs well, insulators require particular qualities in their insulating materials. Materials used to make insulated cables and wires need to be malleable so that they can bend without breaking. On the contrary, the materials that are used to hold those electrical lines need to be exceptionally sturdy. This illustrates how insulating materials' desirable qualities change depending on their eventual purpose. The two most crucial characteristics of an insulating material are dielectric strength as well as high resistivity. One of the characteristics of a material is its resistivity, which indicates how much resistance it offers to an electric current. Dielectric strength, defined as the voltage an object can withstand before cracking when subjected to an electric field, is expressed in terms of millivolts per millimetre (kV/mm).

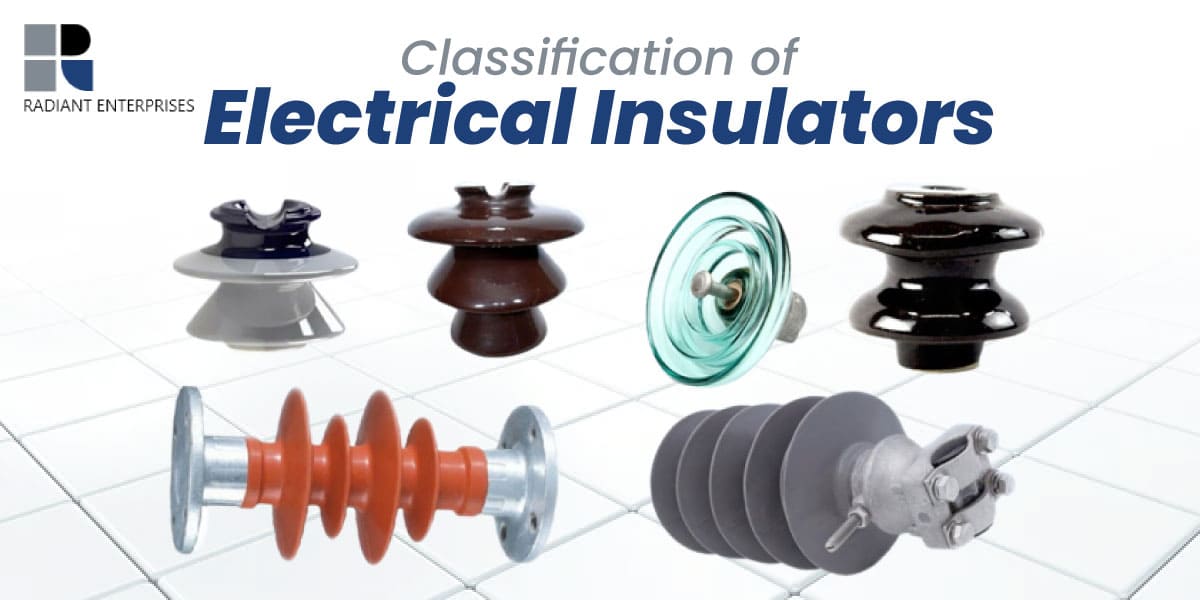

Plastic, rubber, Teflon, mica, PVC, glass, paper, porcelain, as well as ceramic, are only some of the most often used insulating materials along with insulated plugs. Furthermore, suspension insulators, shackle insulators, strain insulators, as well as pin insulators are the most popular kinds of insulators since they are utilised most frequently in overhead power lines. There are numerous different types of insulators, some of which you may or may not be familiar with the following types;

Post-insulators, which feature many petticoats and rain shelters, are typically installed at substations and on overhead power lines. Post insulators are classified as either line post insulators, which are used for voltages between zero and 132 kV, or station post insulators, which can be used for very low or high temperatures.

Stay insulators, as the name implies, are components of stay wires. Ceramic in construction, their design prevents the stay wire from crashing to the ground in the event of insulator failure.

Polymer insulators exported by one of the excellent electrical insulation manufacturers in India, Radiant Enterprises, is actually made of fibreglass rods and polymer weather shelters, and are 90% lighter as compared to porcelain insulators without sacrificing strength. Polymer insulators are often made of PTFE, silicon rubber, EPDM or EPM in addition to these more common materials.

In the 18th century, glass insulators were first used for telephone as well as telegraph lines. In the 19th century, ceramic and porcelain insulators took their place. Toughened glass insulators, which can withstand more abuse over time, were developed as a solution.

The long rod insulators made up of porcelain rods are protected from the elements by metal covers at each end. With long rod insulators, there are no metal connections between the individual units, boosting their durability. These insulators are versatile enough to be utilised in either a suspension or tension setting.