Radiant Enterprises manufactures solid epoxy insulators for Third Rail or Conductor Rail.

Radiant Enterprises makes UV and weather-resistant insulators made of cycloaliphatic epoxy resin compositions, which are used in third-rail insulators(Railway Insulator), power rail insulators, and conductor-rail insulators.

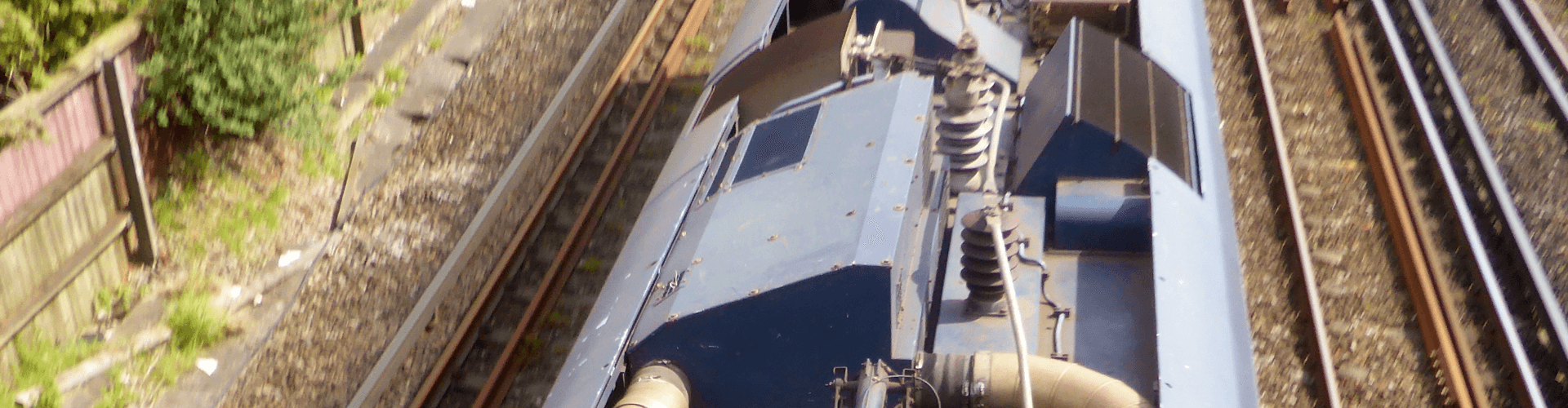

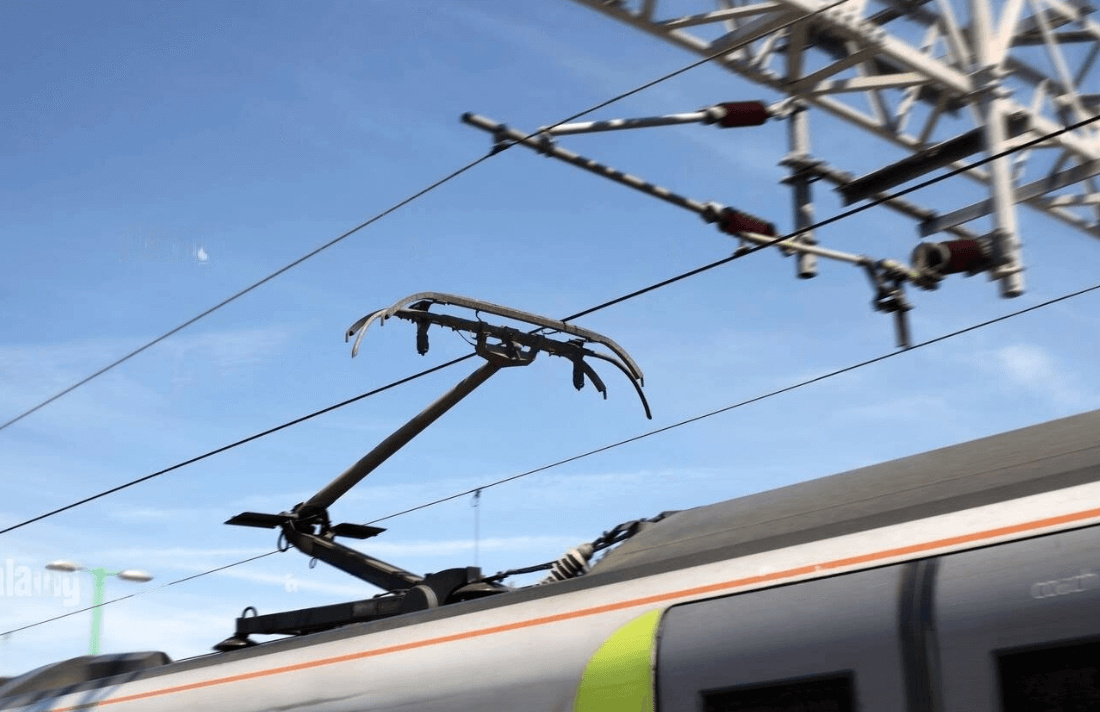

Third-rail systems, which use an additional rail, supply electric traction power (known as a "conductor rail"). The conductor rail is usually located outside the running rails on the sleeper ends in most systems. The conductor rail is supported at 3-6 metre intervals by cycloaliphatic epoxy insulators, ceramic pot insulators, or insulated brackets.

In recent years, epoxy third rail insulators have steadily replaced obsolete ceramic insulators. Cycloaliphatic epoxy insulators have the advantage of being able to be installed in the same area as the existing third rail. There are no further structural alterations that are required. Cycloaliphatic Epoxy conductor rail insulators are especially versatile since they may be cast in virtually any geometry and design.

The cycloaliphatic insulators have passed the EN 45545 and UL 94 V0 tests. For selected models, we also give fire and smoke certifications in compliance with ASTM D2196, D229, D2303, and D495 standards.

We've just included a small sampling of possible casting changes here due to data protection concerns. Radiant has located additional track insulators.