Fill all information details to consult with us to get services from us

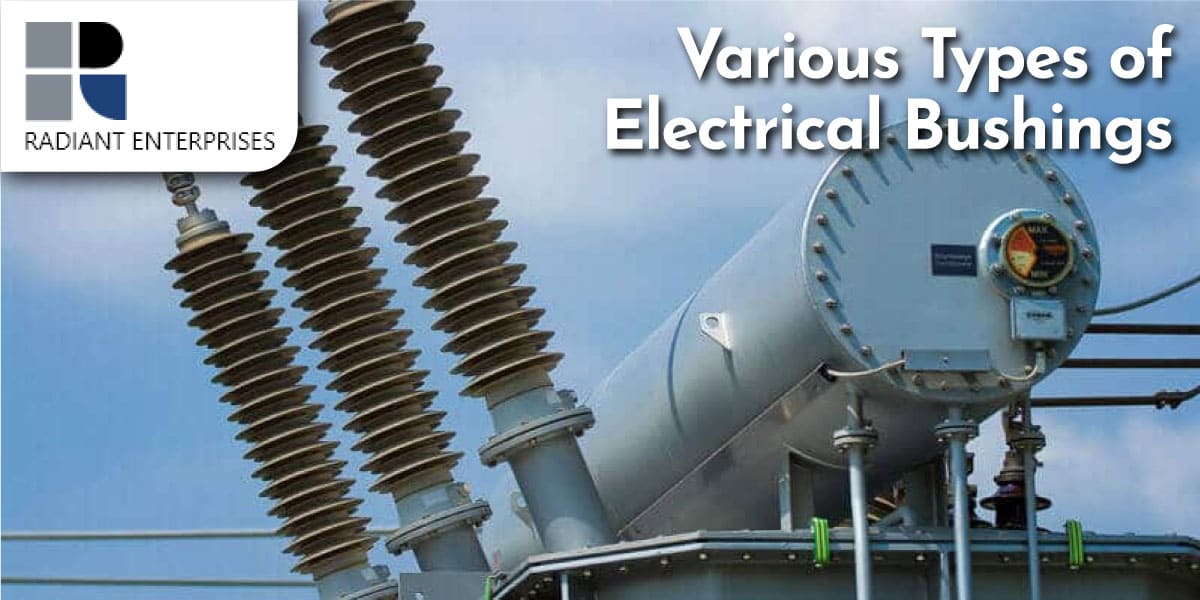

The bushing is a hollow electrical insulator used in electricity that lets an electrical conductor pass safely past a conducting barrier, such as the casing of a transformer or circuit breaker, without making electrical contact with it. For bushings, porcelain is frequently used, but other insulating materials are also employed.

All elements with an electric charge produce an electric field. When an electrified conductor comes close to a material with an earth potential, it can generate extremely strong field lines, especially if the field lines are forced to curve abruptly around the earthy substance. The bushing shapes and strengthens the field while also reducing electrical strains in the insulating material.

Radiant Enterprises is the most popular and distinguished Transformer Bushing manufacturer in USA.

Porcelain was used in the first bushing designs for both indoor and outdoor use. Porcelain was first utilised because of its advantages of being impermeable to moisture once sealed by a fired glaze, as well as its inexpensive cost of production. The fundamental disadvantage of porcelain is that it has a low linear expansion value, which necessitates the use of flexible seals and large metal fittings, both of which cause manufacturing and operating issues.

A basic porcelain bushing is a hollow porcelain shape that fits into a hole in a wall or metal casing and allows a conductor to pass through its centre, connecting to other equipment on both ends. Bushings of this sort are frequently constructed of glazed wet-process fired porcelain. To help equalise the electrical potential gradient along the length of the bushing, a semi-conducting coating can be utilised.

To offer further insulation, the inside of the porcelain bushing is often filled with oil, and bushings of this kind are widely employed up to 36 KV, where higher partial discharges are permissible.

For unheated indoor and outdoor applications where partial discharge is necessary to comply with IEC60137, paper and resin insulated conductors are utilised in conjunction with porcelain.

If you are looking for the best and the leading Transformer Bushing manufacturer in Mexico, Radiant Enterprises is the name you can trust.

Although most high-voltage bushings are made of resin-impregnated paper insulation around the conductor with porcelain or polymer weather sheds for the outdoor end and occasionally for the indoor end, resin (polymer, polymeric, composite) insulated bushings are commonly used for high voltage applications.

Paper was another early kind of insulation, but it is hygroscopic and absorbs moisture, which is harmful and is hampered by rigid linear designs. Because of its shape flexibility and superior dielectric strength, cast resin technology has dominated insulated products since the 1960s.

Paper insulation is typically saturated with oil (historically) or resin (more commonly today). When using resin, the paper is either film coated with phenolic resin to create synthetic resin bonded paper (SRBP) or impregnated with epoxy resins after dry winding which in turn creates the resin-impregnated paper (RIP) popularly known as epoxy resin impregnated paper (ERIP).

Up to voltages of roughly 72.5 kV, SRBP insulated bushings are commonly utilised. However, at 12 kV, there is a requirement to control the external electrical field and level out the internal energy storage, which reduces paper insulation's dielectric strength.

Metallic foils can be introduced during the winding process to increase the performance of paper insulated bushings. These operate to stabilise the generated electrical fields by utilising the capacitance effect to homogenise the internal energy. The condenser/capacitor bushing was created as a result of this functionality.

During the winding operation, very fine layers of metallic foil are inserted into the paper to create the condenser bushing. The capacitive effect created by the inserted conductive foils dissipates electrical energy more uniformly across the insulated paper and minimises electric field stress between the energised conductor and any earthed substance.

Radiant Enterprises is one of the excellent and most trusted Transformer Bushing manufacturer in Europe.

Condenser bushings provide electric stress fields around the mounting flange that are substantially less potent than designs without foils, and when combined with resin impregnation, produce bushings that may be utilised at service voltages exceeding one million with remarkable success.

Resin materials have been used for all types of bushings up to the greatest voltages since the 1960s. In several product categories, the versatility of adopting a castable form of insulation has replaced paper insulation and now dominates the existing insulated bushing industry.

Controlling electric stress fields is just as critical as controlling paper insulation. At voltages below 25 kV, resin insulation has a higher dielectric strength than paper and requires less stress control. Some compact and high-rated switchgear designs, on the other hand, have earthed materials closer to bushings than in the past, and these designs may necessitate stress control screens in resin bushings working at low voltages as low as 12 kV. Fixing points are frequently merged with the main resin form, posing fewer earthing issues than the metal flanges used on paper bushings.

However, in resin insulated bushings with internally cast screens, care must be taken to ensure that the benefit of electrical stress field control is not offset by an increase in partial discharge caused by the difficulty of eliminating microvoids in the resin around the screens during the casting process. As voltages rise, the necessity to avoid voids in resin becomes more critical, and it's common to switch to resin-impregnated, foiled paper insulation for bushings rated beyond 72.5 kV.