Radiant has a long-standing supplier connection with a number of well-known international railway technology companies. This is built on a foundation of not only trust, but also regular internal audits.

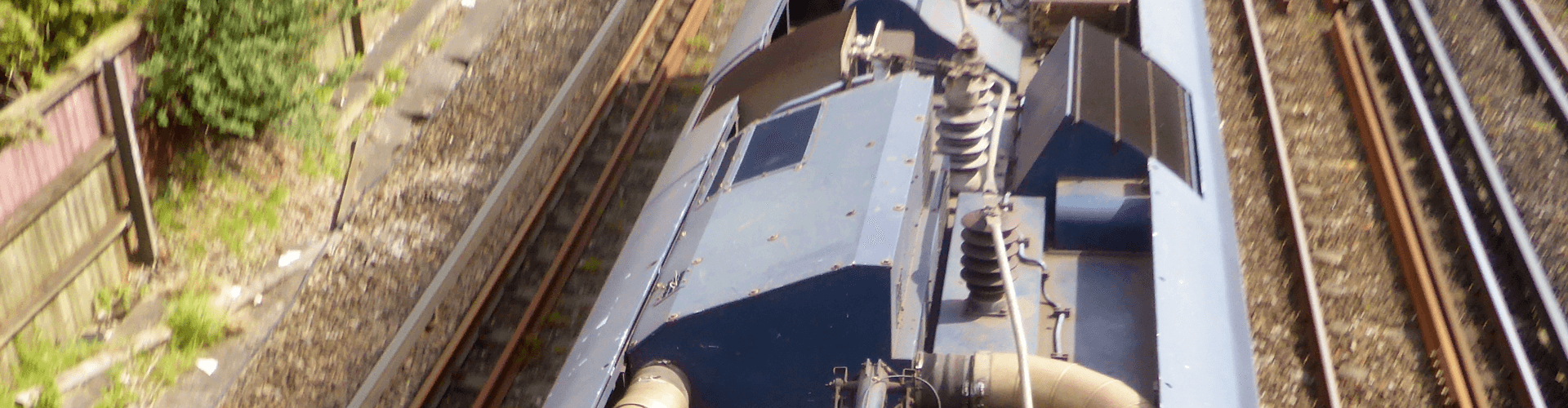

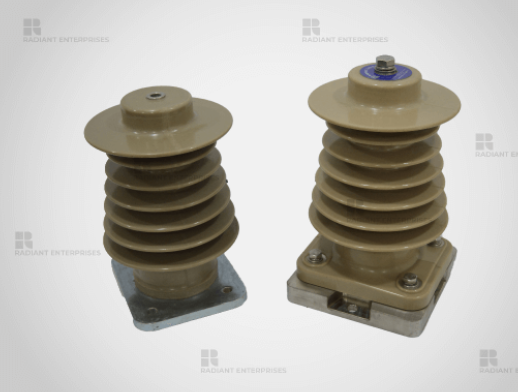

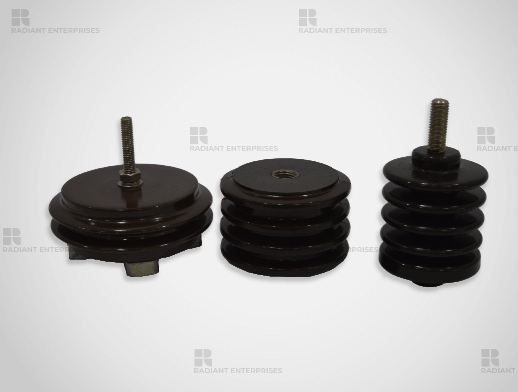

Radiant manufactures third rails and rolling stock insulators for railways, including railcars and locomotives (Pin-Insulators, Pantograph Support Insulators).

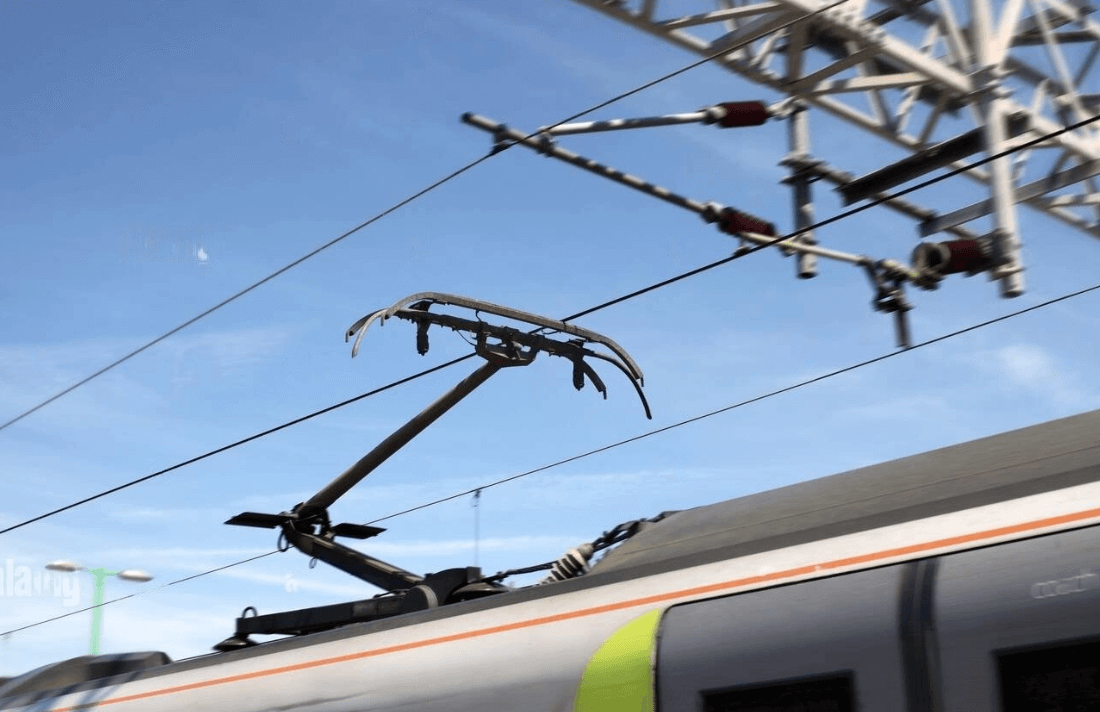

Radiant manufactures insulation for both mainline and metro locomotives. The biggest brands in pantograph production, as well as a considerable number of train operating organisations, are among our customers. The biggest brands in pantograph manufacturing, as well as a considerable number of train operating companies, are among our customers.

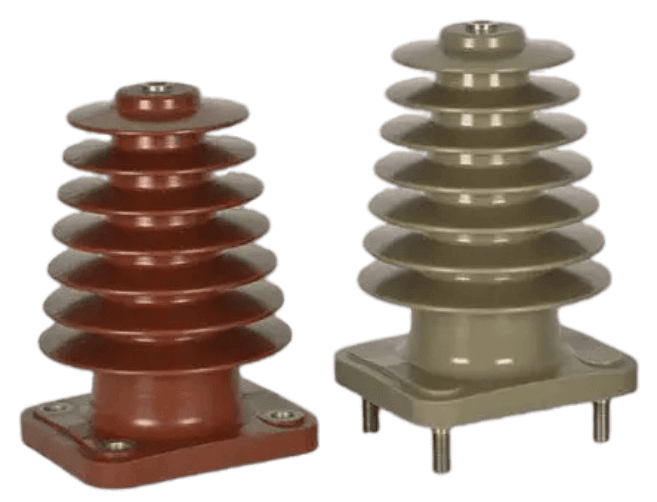

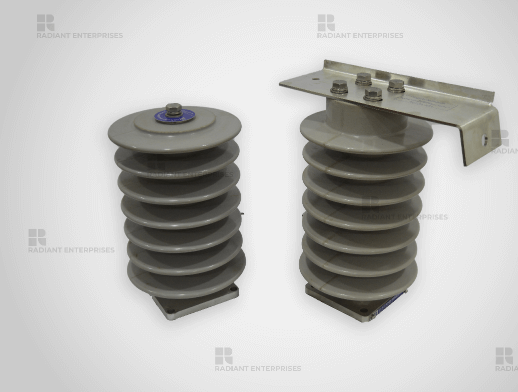

Radiant can make roof top bushings that are either customised to fit particular specifications or designed wholly new in partnership with the customer, in addition to typical goods such as support insulators and third rail insulators.

The cycloaliphatic outdoor cast-resin passed the EN 45545 and UL 94 V0 tests. For selected models, we also give fire and smoke certifications in compliance with ASTM D2196, D229, D2303, and D495 standards.

Our references and certificates prove to our capacity to think beyond the box, as well as our performance and dependability.

Post Insulators, Pantograph Insulators, Roof Insulators, Third Rail Insulators, and Bushings are just a few of the goods we make to use them in the following fields.

- E- locomotives

- Tramways

- Metro systems

- Electronic mobility

- traffic Infrastructure